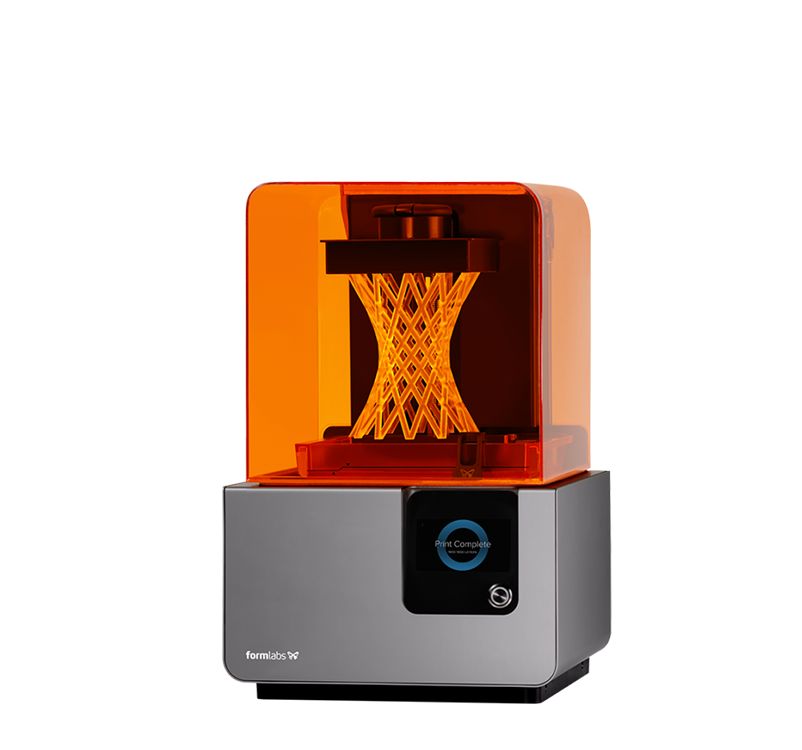

3D4MED is equipped with all the hardware and software necessary to perform the entire process, from medical images elaboration to the production of the 3D printed model. We are equipped with:

Thanks to the 3D printers available in the laboratory, we can select the most suitable technology according to the destination of use of the 3D printed model.

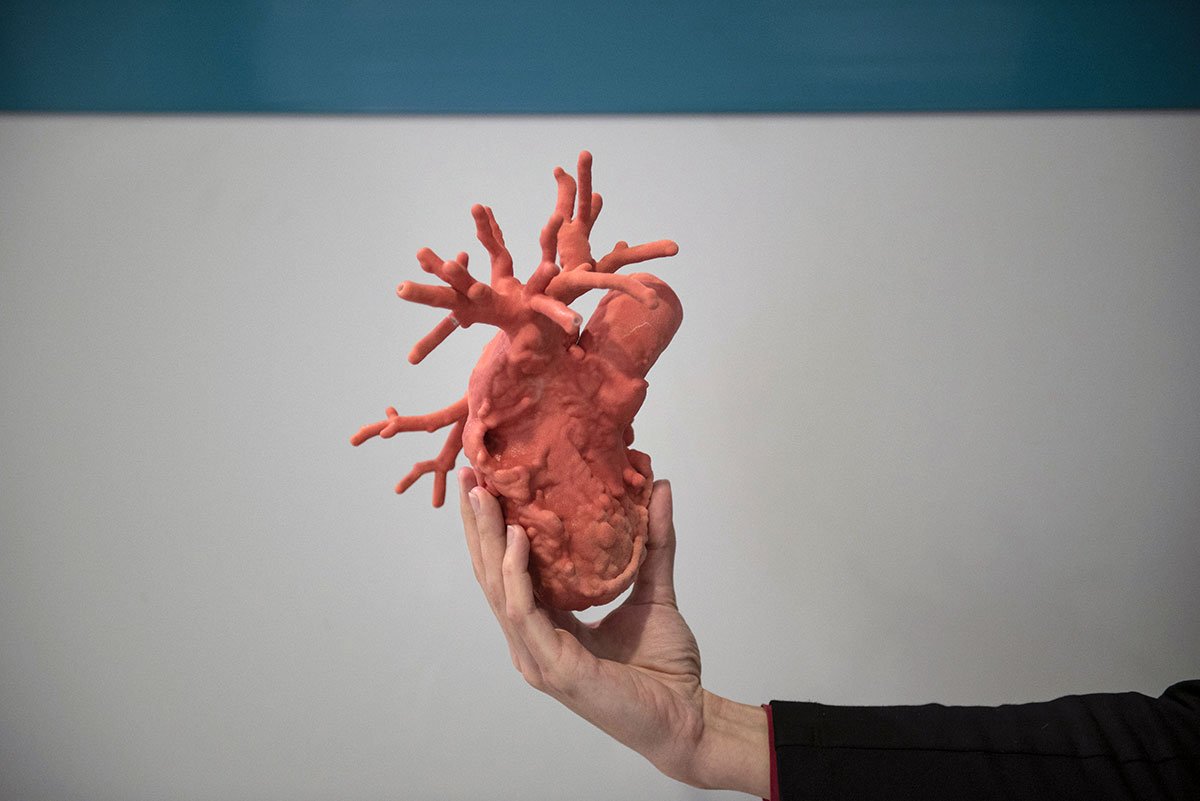

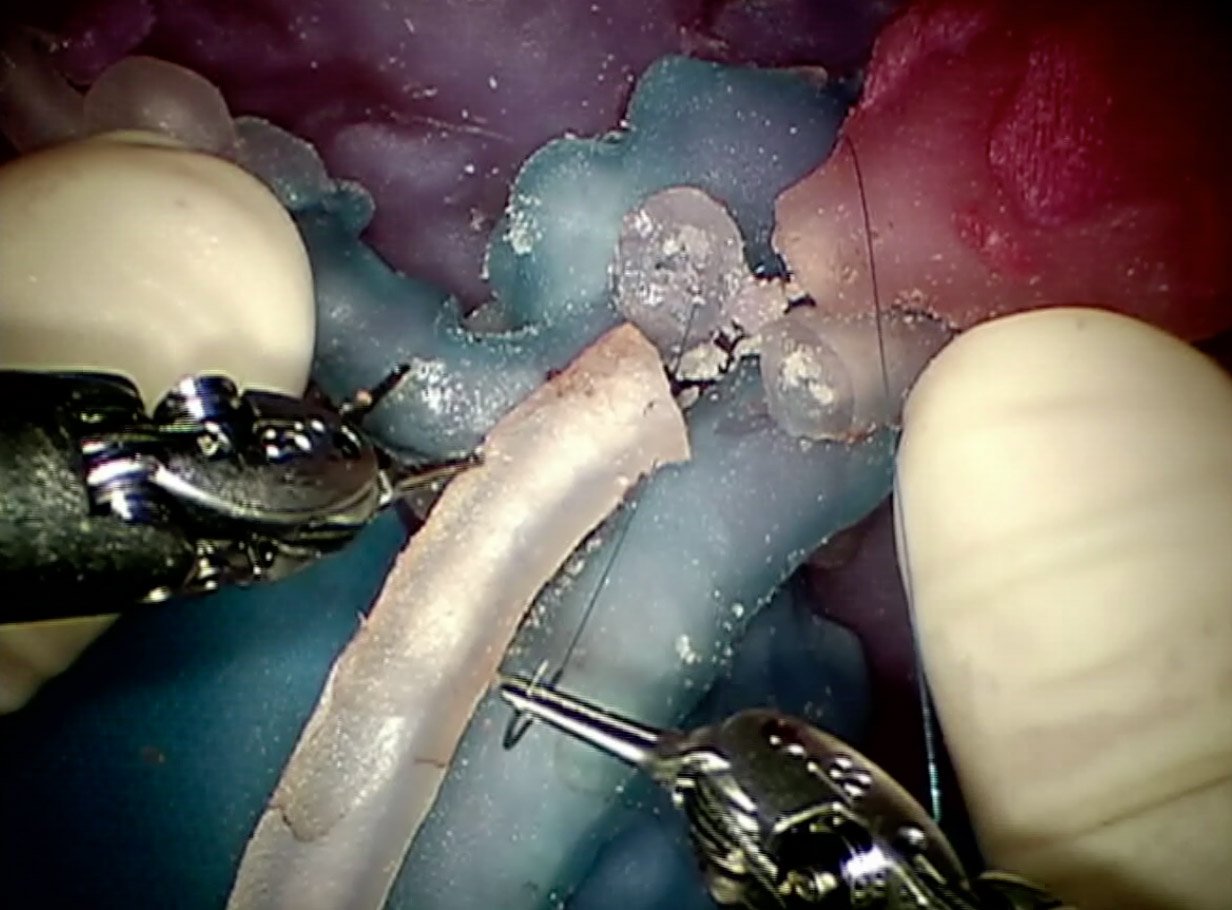

Using an Objet260 Connex3, 3D models can be printed in colored and deformable resins. This technology enables the tuning of deformability and transparency features, allowing to replicate both morphology and mechanical properties of soft tissues. Deformable models can be particularly useful for surgical simulations performed through robotic or laparoscopy approaches: the surgeon can perform the surgery directly on the 3D printed model, anticipating and preventing possible issues related to the specific surgical procedure.

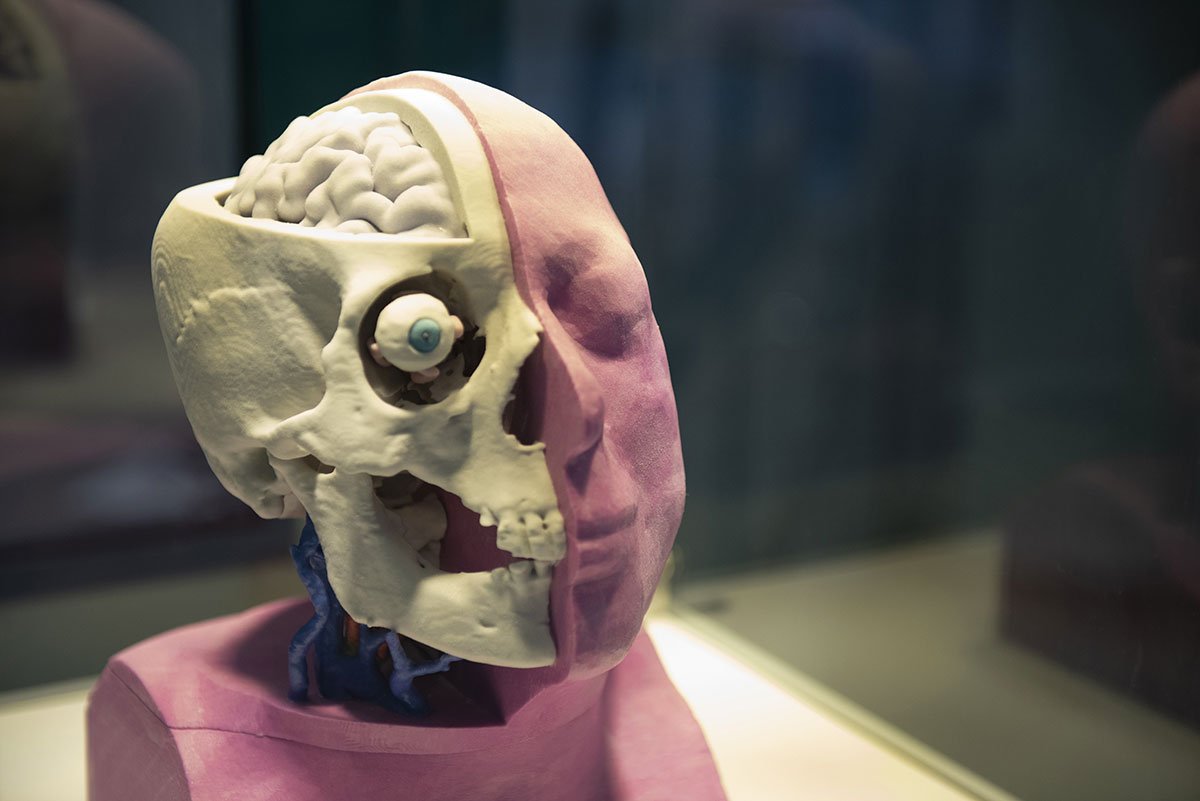

The Projet460 Plus 3D printer enables the production of plaster models with a full-scale chromatic resolution. The availability of a full-color resolution is extremely helpful for the manufacturing of models intended for didactic purposes or to explain the procedure to the clinical staff and to the patient, thanks to an effective chromatic discrimination of all the involved anatomical structures.

Plaster 3D printed models can be particularly useful for the planning of interventions involving bony structures. Since the 3D printing material faithfully replicates bones mechanical response, plaster models can be used to model templates, to apply plaques and to select the most suitable surgical instruments before entering the OR and perform the surgery.

Thanks to a FormLabs FORM2 and to the use of a transparent photopolymer resin, we can produce models particularly useful for vascular surgery. Models allow the surgeon to better appreciate the vascular morphology and possible anomalies, to test the apposition of vascular endo-prostheses and to assess their positioning, supporting the choice of the most suitable device for the specific clinical case.