Eng. Francesca Rotini

A Bone-Remodeling Driven Numerical Framework for Hip Prosthesis Design

The aim of the study is to reduce prosthesis failures caused by the stress shielding phenomenon with a numerical workflow through which we first simulate the bone remodelling process with the finite element analysis (Ansys) and then, we use the resulting information to guide a patient-specific implant’s topology optimization

Clinical Problem

Total hip arthroplasty is the only treatment for several types of diseases.

However it isn’t a permanent solution since it requires a revision surgery after 15/20 years in according with the current prosthesis lifespan: this is a big inconvenient, especially for younger patients.

The causes of prosthesis failures are different: the most common is the aseptic loosening caused by the bone resorption due to stress shielding, which rises for the stiffness differences between the metal alloy component and the surrounding bone.

Current workflow

We developed a numerical workflow to simulate the bone remodeling process in order to predict the bone resorption and prosthesis failures: starting from the patient CT scans, we retrieve the 3D model of the femur with the prosthesis inside and then, with a finite element analysis, we implement an in house code to simulate di bone remodeling process. We obtain a map which identifies the resorption zones and apposition zones.

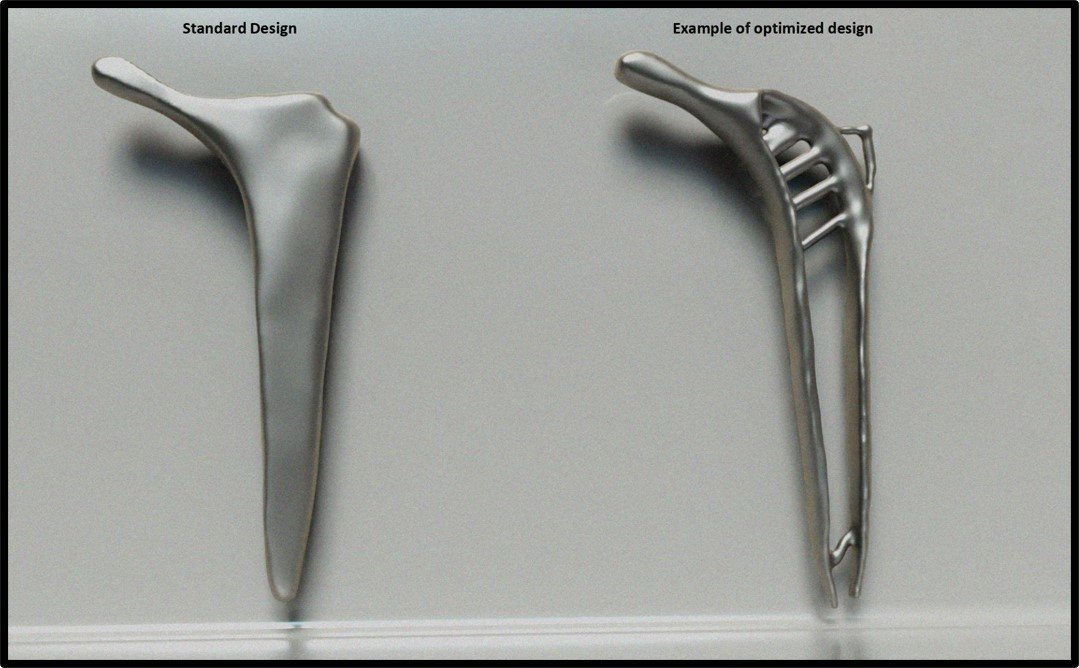

We would like to use the simulation results to guide a patient specific prosthesis topology optimization, in order to identify the right geometry of the implant to minimize the bone resorption phenomenon.

New proposed step forwards

The hip prosthesis topology optimization has been largely used in the last decades in literature, but no one take directly into account the bone resorption’s problem.

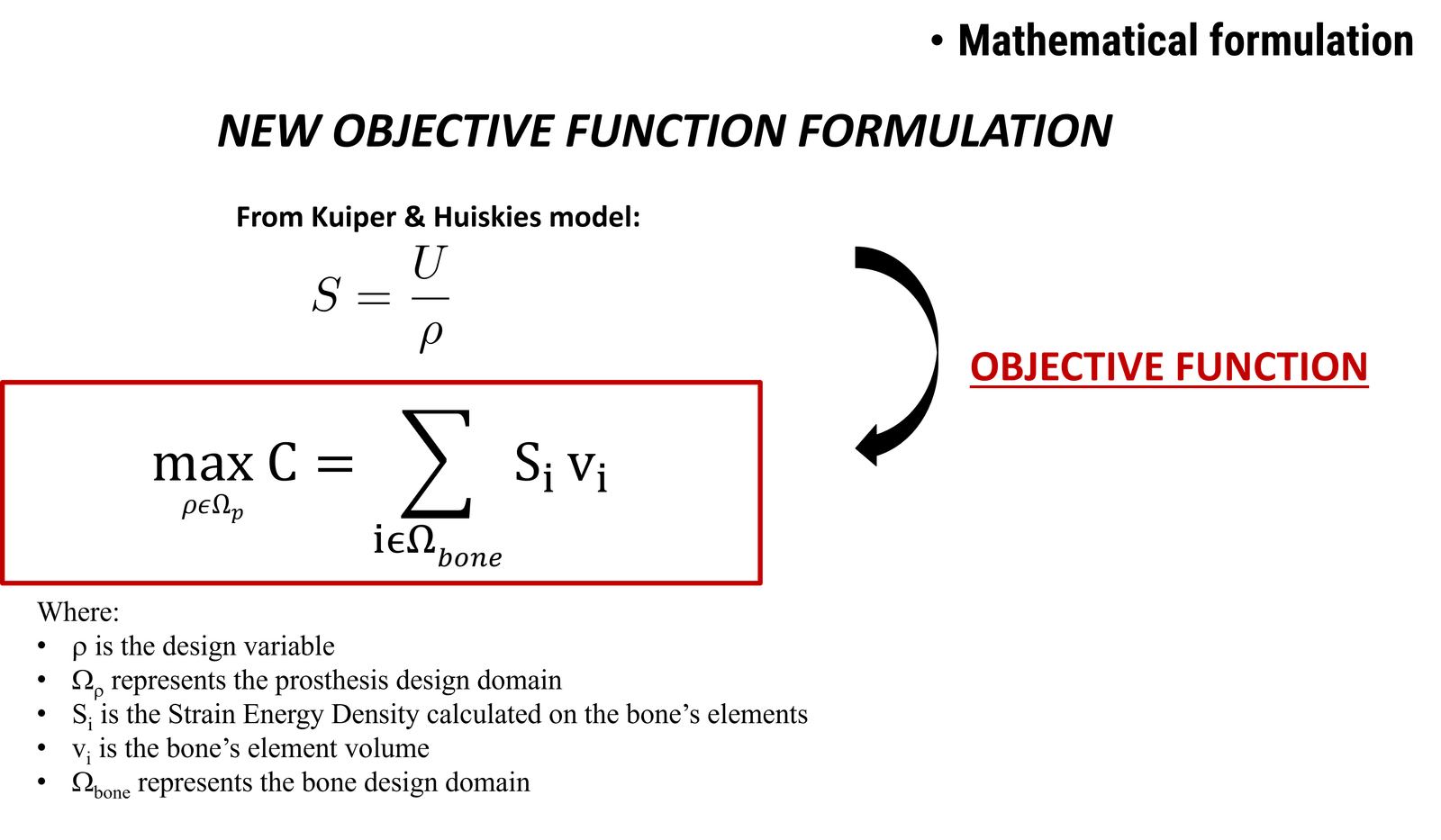

We want to introduce a new type of formulations that consider the bone resorption to guide the topology optimization procedure and, in particular, the objective function we want to implement is the maximization of the bone compliance since, this way, we’ll maximize the Strain Energy that will bring the bone apposition in the bone remodeling process.

We look forward with our research to complete the mathematical formulation with right constrains to avoid trivial results and with a numerical method to carry on the topology optimization